+86 139 5134 9332 customer601@sunhongco.com

Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

The Function of Paper Machine Press Section

1. Remove moisture from the paper sheet:

2. Increase the bonding strength of fibers in the paper sheet;

3. Eliminate mesh marks on the paper sheet;

4. Transfer the wet paper sheet from the forming section to the dryer section.

But for paper machines that produce high absorbency paper, the press section mainly plays a role in pick up the paper.

From the perspective of removing moisture from wet paper sheet, the role of the press section is very obvious.

The dehydration efficiency of the press section is related to the structure, combination, press roll, press felt, etc. of the pressing section. Modern new technologies can increase the dryness of paper sheets exiting the press section to 48% -50%.

Dehydration limitations:

① Due to the form and equipment of water, it mainly removes free water, while other forms such as bound water are difficult to remove; Even if the efficiency of removing free water is improved, it will still be limited by the equipment in the press section.

② Restricted by pressure: Excessive pressure can cause wet paper to crush (embossing).

The "solidification" effect of the pressing and dehydration process on paper sheets is generally believed to start forming hydrogen bonds on wet paper sheets at a dryness of about 40%, while pressing increases the dryness of wet paper sheets from about 20% to over 40%. Some researchers refer to the process of forming bonds as the curing effect on paper sheets.

The effect of pressing on the structural properties of paper sheets. Pressing can increase the contact between fibers, increase the bonding area between fibers, and thus improve the bonding strength of fibers.

Press Roll for Paper Machine Press Section

The press section usually consists of 2-4 sets of press rolls.

The new paper machine replaces the previous sets of presses with composite presses.

Types of construction types of press rolls: flat press roll (stone roll, rubber roll), vacuum press roll, groove press roll, blind hole press roll, adjustable crown roll, wide press zone and shoe press.

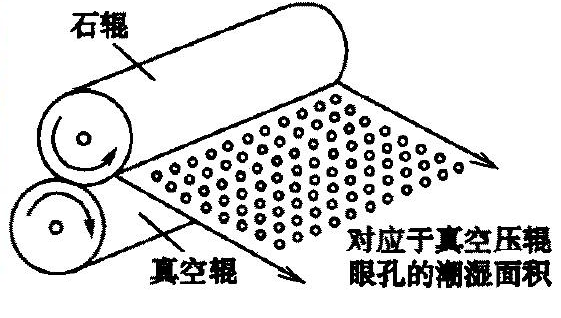

Vacuum Suction Press Roll

Mostly used for medium and high-speed paper machines

Upper roll: Stone roll

Lower roll: Rubber coated suction press roll

Blind hole on the surface of suction press roll: diameter 4mm, opening rate: 15%~25%

On the one hand, it is necessary to have a sufficient amount of dehydration; At the same time, it is also necessary to consider that the opening will affect the strength of the roller and leave "shadow marks" on the paper.

Choosing a thin and fluffy press felt, a softer adhesive layer, and using smaller holes can alleviate this paper disease.

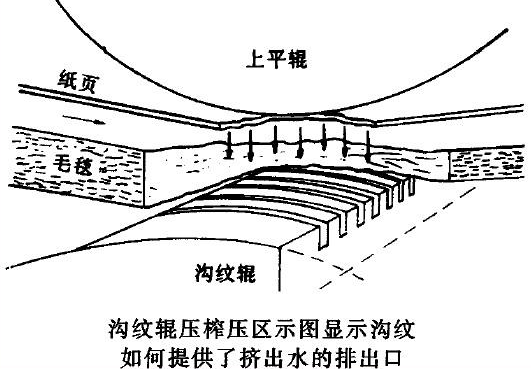

Groove Press Roll

Upper roll: Stone roll

Lower roll: Rubber coated groove press roll

Groove shape: Square groove is the best

Width: 0.5~0.6 mm

Depth: 1.0~3.5 mm

Groove spacing: 3.2-3.6 mm

Opening rate: 16%~19%

Features:

(1) Simple structure, easy to modify, no need to increase power consumption

(2) Wide adaptability: suitable for various paper machines and paper types

(3) Significant effect (vertical dehydration advantage)

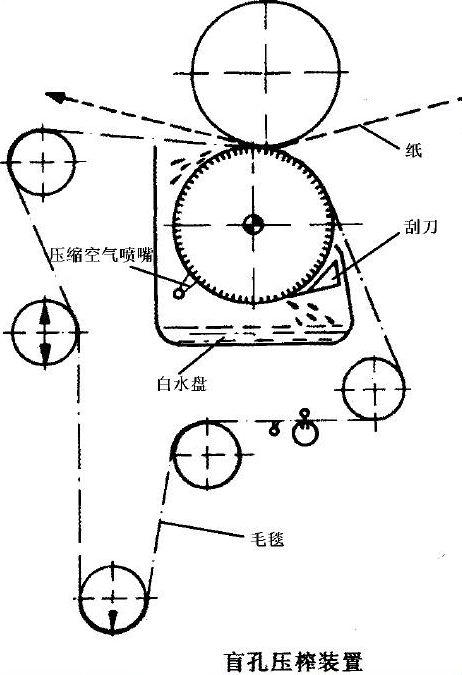

Blind Hole Press Roll

Upper roll: Stone roll

Lower roll: blind hole press roll

Aperture: 2 mm

Depth: 12-15mm

Opening rate: 25%~30%

Features:

The area of the pressure zone opening is larger than that of the groove

The roll surface is softer than the grooved press roll surface

Make the horizontal moisture of the paper sheet more uniform

Press felt have a longer lifespan, etc