+86 139 5134 9332 customer601@sunhongco.com

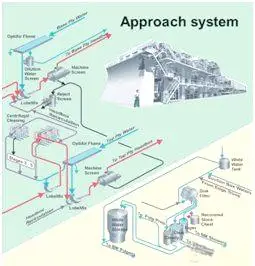

1.Stock Preparation

The core task of the stock preparation process is to ensure that the pulp can be smoothly transported to the headbox after undergoing fine blending, screening, impurity removal, chemical addition, and concentration control processes. In the stock preparation processes, key equipment includes high-efficiency impurity remover, precision pressure screen, deaerator, and multiple plates of white water, which work together to create a high-quality starting point for the birth of paper.

2. Headbox and Paper Web Forming

The core concept of the headbox is to provide ideal preparation conditions for the formation of paper sheets. It can evenly spread the paper material along the width direction of the paper machine, ensuring that key parameters such as pressure, speed, flow rate, concentration, and fiber orientation are controllable and uniform. In addition, the headbox can effectively disperse pulp fibers, prevent them from flocing, and provide and maintain a stable sizing head and pulp web ratio according to process requirements.

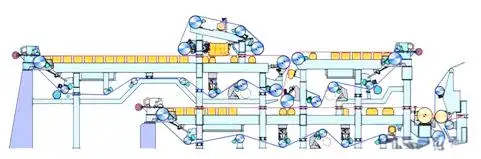

3. The Role of Wire and Press Section

The core task of the paper machine wire section is to evenly spread the pulp sprayed from the headbox on the forming fabric surface. This process involves multiple steps such as edge setting, pulp jumping, step-by-step dehydration, and interlayer composite, with the ultimate goal of creating a wet paper web with a certain dryness and strength.

The core mission of the paper machine press section is to deeply dehydrate the wet paper web conveyed by the web department to improve its dryness and enhance the initial strength of the paper. In addition, the department also uses various press roll surface treatment technologies to finely decorate the surface of paper.

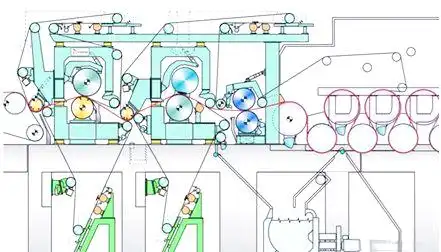

4. Drying and Surface Treatment

The core task of the paper machine dryer section is to receive the paper web conveyed by the press section and use the heat transfer effect of the dryer cylinder to deeply remove moisture from the paper. This step aims to ensure that the paper reaches the required moisture content for the next process.

The purpose of surface sizing is to cover a layer of adhesive on the surface of the paper to enhance its surface strength, improve its water resistance, and help improve the warping problem and interlayer adhesion of the finished paper.

The calendering machine is divided into two types: hard calendering and soft calendering. Its core purpose is to improve the flatness of the paper and optimize the thickness curve of the paper web. For coated cardboard, hard calendering can provide a higher quality base material for the coating machine, thereby ensuring the coating effect. And soft calendering further decorates the coating surface, effectively improving multiple indicators such as glossiness of the finished paper.

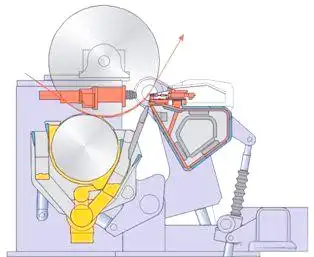

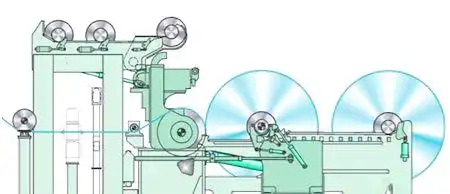

5. Reel and subsequent processes

The core task of a coating machine is to evenly apply coating or adhesive on the surface of paper, aiming to enhance the smoothness and glossiness of the paper and improve its printability.

The purpose of the reel process is to orderly roll the paper processed by the coating machine into a roller shape, in order to provide suitable raw materials for the subsequent rewinding process.

At this point, the basic production process of paper is nearing completion. The subsequent processes of rewinding, rewinding, fully automatic conveyor chain plate, packaging offline, labeling, and roll wrapping are all completed by auxiliary equipment in papermaking production. A comprehensive understanding of these processes will provide us with a key foundation for in-depth analysis of each step.

Contact Us