+86 139 5134 9332 customer601@sunhongco.com

Views: 0 Author: Site Editor Publish Time: 2025-05-14 Origin: Site

Paper machine press section is very important part, it connect the wire part and dryer part. When the wet paper sheet transfer to press section, the press felt support the wet paper sheet to further remove moisture of the paper sheet, and finishing paper surface to give more strength of the press felt. The press felt is most important fabric for press section.

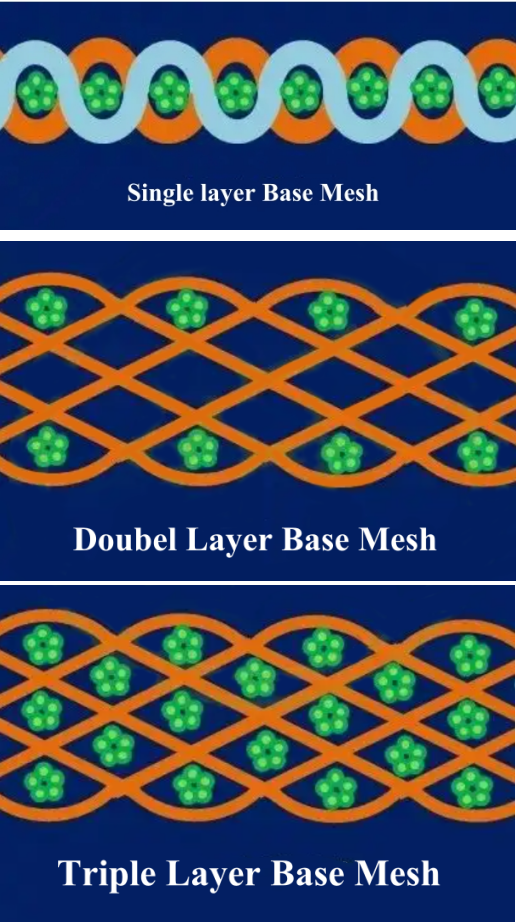

The base mesh layer of press felt is like the felts’ bone frame, it determined the limit of felt weight, air permeability, moisture, and stability. The base mesh layer is woven by carding fiber, monofilament, multifilament and sandwich thread. The woven base layer can be divided into single layer mesh, double layer mesh, triple layer mesh, and laminated layer mesh.

Another one is non-woven base layer, this type base layer is usually used on culture paper or white coated board paper. Its mainly feature is fast dewatering, but woven type base layer have stronger anti- squeeze ability and long life service.

The diameter of batt fiber directly affect felt’s air permeability, surface flatness and dewatering function. It’s very important for felt running performance. The batt fiber mainly affects the fineness of the surface of the felt. It is usually showed by the dtex value of surface batt. dtex refers to the weight of ten thousand meters of fiber corresponding to Texas, measured in grams per 10000 meters. The smaller the value, the finer the surface batt, which can achieve a smoother paper surface effect. At the same time, using the same or different surface batt dtex values for the top and bottom felt can effectively assist in the transfer of the paper web. Generally speaking, the paper is easy to adhere and transfer towards the direction of the felt with lower dtex values and finer surface.

In addition, the batt fiber also affects the fiber density and internal space stability of the felt. When the batt density is too low, it is difficult for the inside of the felt to be quickly filled with moisture and reach saturation, the felt has a long adaptation period, and the paper machine speed cannot be started; When the batt density is too high, the felt is easy to be compacted and dirty, making it difficult to clean, resulting in rapid closure of the felt. Due to insufficient dehydration capacity, it is removed from the machine in advance.

Working Principle of Pressure Screen And Its Application in Paper Machine

Impact of Refiner Plate Types on Pulping Index And Paper Quality

Do You Know The Basicly Structure of Paper Machine Press Felt?

What Are The Factors That Affect The Stability of Press Felt? How Can We Control It?

What is forming a fabric with a single thread and needle called?

Efficiency Unleashed: Innovations in Corrugated Paper Conveyor Belt Technology