+86 139 5134 9332 customer601@sunhongco.com

Views: 0 Author: Site Editor Publish Time: 2025-12-26 Origin: Site

The vacuum suction couch roll on the paper machine is mainly dehydrated by vacuum suction force. Its advantages include easy operation, high dehydration rate, minimal wear of the forming fabric, and convenient paper feeding. The use of suction couch roll in paper machines can increase the dryness of wet paper sheets to over 20%, while high-speed paper machines can achieve 27%.

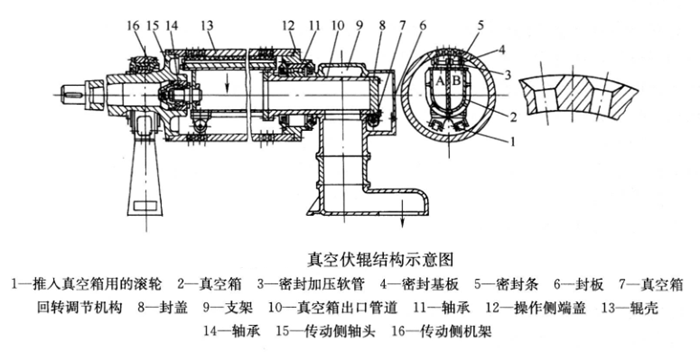

The suction couch roll consists of two main components: a vacuum chamber and a roll shell. The roll shell is generally made of stainless steel 304/316. The contact holes between the shell and the forming fabric are all countersunk circular holes. The circular hole is small inside and large outside to facilitate the suction and ejection of white water. To fully utilize the function of vacuum suction couch roll, it is necessary to regularly maintain the cleanliness of the holes on the roll shell. To meet the needs of forming fabric replacement work, the vacuum suction couch roll can be designed as a cantilever, and during normal production, its two ends are still supported on the bearing seat.

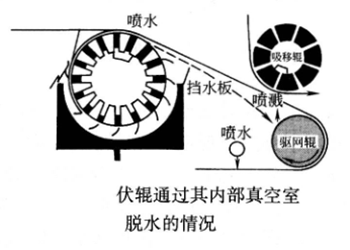

The dehydration principle of vacuum suction couch roll is similar to that of vacuum suction box. The vacuum suction couch roll is dehydrated through its internal vacuum chamber, and its dehydration strength mainly depends on the vacuum degree inside the vacuum chamber. Dehydration time and the amount of air passing through the wet paper are only secondary factors. The increase in vacuum degree has a significant impact on the dewatering ability of the roller, such as a vacuum degree increase of 5.3kPa, which can increase the dryness by 1% -1.5%. The dehydration time on the roller is very short.

When the paper machine speed is low, water and air enter the roll and enter the roll vacuum chamber. In this case, a water vapor separator system must be used to separate air and water, so that white water does not enter the vacuum generation system.

At higher speeds, most of the moisture extracted from the wet paper does not have time to enter the vacuum chamber inside the roller. Usually, 70% -80% of the moisture remains in the small holes on the roller surface or in the mesh of the forming fabric.

The higher the paper machine speed, the less water enters the vacuum chamber. The moisture left in the roll hole is thrown out by the high-speed airflow rushing into the small hole at the moment when the roll hole passes through the vacuum box. Therefore, it is necessary to install a white water tray and a water blocking plate for the press roll to prevent the water thrown out from returning to the entrance side of the meshing area between the press roll and the forming fabric or splashing onto the driving wire roller through the white water tray.

The commonly used vacuum suction couch roll are single chamber, but there are also double chamber and triple chamber ones.

The range of use for the vacuum degree of the suction couch roll is 46-74kPa. When installing a soft adhesive layer coated upper roller on the suction couch roll, the tightness of the wet paper web can be increased. When the paper machine speed is higher than 200m/min, a steel pipe coated upper roll (with a hardness of 30-35 degrees Shore) should be installed to improve the vacuum degree and dehydration capacity of the upper roll. The line pressure between the rollers is 981-1960N/m. There should be a spray water device above the entrance side of the upper roll.

After the speed of the paper machine exceeds 400m/min, it is necessary to further strengthen the dewatering of the rolls, so that the dryness of the paper web after the rolls reaches 20% -22%, in order to smoothly guide the paper web from the rolls to the press section. It is best to increase the vacuum degree of the roller to 60-75kPa for this purpose.

Increasing the vacuum degree on a single chamber suction couch roll will result in a significant increase in the power consumption of the vacuum pump required for the roller. Using multi chamber suction couch roll instead of single chamber suction couch roll, that is, using several narrower vacuum chambers with gradually increasing vacuum degree to replace a wider high vacuum chamber, can achieve the same dehydration effect while saving the power consumption of the vacuum pump.

The structure of multi chamber suction couch roll is relatively complex and has a large diameter, usually used in large paper machines. The first vacuum chamber of the double chamber suction couch roll has a water absorption width of 150-250mm and a vacuum degree of 50-55kPa; The second chamber is 100-150mm wide and has a vacuum degree of 70-75kPa. The vacuum degree of each chamber on the three chamber suction couch roll is usually 20-30, 40-50, and 70-80 kPa. The suction width of a single chamber suction couch roll is generally not greater than 230mm. The total suction width of a multi chamber suction couch roll is not greater than 400mm.

Contact Us